Option One

On Zoom

Instructor-Led

Please contact Alex to arrange Zoom Classes

Table of Contents

Module 1. Introduction to Statistical Process Control, HACCP and FSMA

Module 2. Descriptive Statistics

Module 3. Inferential Statistics

Module 4. Probability

Module 5. Exploratory Statistics

Module 6. Geostatistics

Module 7. Statistical and Statistical Process Control (SPC) Software

Module 8. Six Sigma, Lean Six Sigma, Check Sheet and Food Processing

Module 9. Artificial Intelligence and Statistical Process Control

Module 10. Using Pareto Charts for Quality and Safety

Module 11. Histograms, Normal Distribution and other Charts

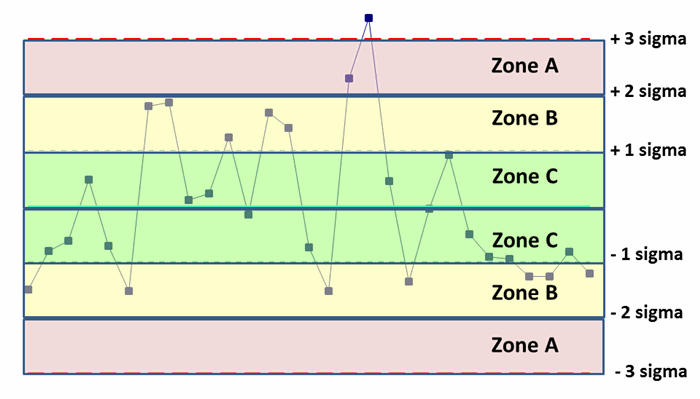

Module 12. Control Charts

Module 13. Scatter Plots and Correlation Coefficients

Module 14. Stratification Tools

Module 15. Ishikawa Diagram (Cause and Effect Diagram)

Module 16. The Failure Effects Mode Analysts ( FEMA)

Module 17. Hypothesis and Hypothesis Testing

Module 18. Process Mapping and Value Stream Mapping (VSM)

Module 19. Quality Control and Six Sigma

Module 20. Test Statistics

Module 21. Prerequisite Programs

Module 22. Preliminary Steps

Module 23. Food Safety Hazards

Module 24. Conduct Hazards Analysis

Module 25. Determine Critical Control Points

Module 26. Establish Critical Limits

Module 27. Establish Monitoring Procedures

Module 28. Establish Corrective Action procedures

Module 29. Establish Verification Procedures

Module 30. Establish Record-Keeping and Documentation Procedures

Module 31. Implement, maintain, and reassess HACCP plans and systems

Option Two

Self-Paced

To be

Completed in 60 Days

Table of Contents

Module 1. Introduction to Statistical Process Control, HACCP and FSMA

Module 2. Descriptive Statistics

Module 3. Inferential Statistics

Module 4. Probability

Module 5. Exploratory Statistics

Module 6. Geostatistics

Module 7. Statistical and Statistical Process Control (SPC) Software

Module 8. Six Sigma, Lean Six Sigma, Check Sheet and Food Processing

Module 9. Artificial Intelligence and Statistical Process Control

Module 10. Using Pareto Charts for Quality and Safety

Module 11. Histograms, Normal Distribution and other Charts

Module 12. Control Charts

Module 13. Scatter Plots and Correlation Coefficients

Module 14. Stratification Tools

Module 15. Ishikawa Diagram (Cause and Effect Diagram)

Module 16. The Failure Effects Mode Analysts ( FEMA)

Module 17. Hypothesis and Hypothesis Testing

Module 18. Process Mapping and Value Stream Mapping (VSM)

Module 19. Quality Control and Six Sigma

Module 20. Test Statistics

Module 21. Prerequisite Programs

Module 22. Preliminary Steps

Module 23. Food Safety Hazards

Module 24. Conduct Hazards Analysis

Module 25. Determine Critical Control Points

Module 26. Establish Critical Limits

Module 27. Establish Monitoring Procedures

Module 28. Establish Corrective Action procedures

Module 29. Establish Verification Procedures

Module 30. Establish Record-Keeping and Documentation Procedures

Module 31. Implement, maintain, and reassess HACCP plans and systems

Option Three

Onsite

Your Site or

Hermosa Beach, Los Angeles, California

Contact Alex to Arrange Classes

Table of Contents

Module 1. Introduction to Statistical Process Control, HACCP and FSMA

Module 2. Descriptive Statistics

Module 3. Inferential Statistics

Module 4. Probability

Module 5. Exploratory Statistics

Module 6. Geostatistics

Module 7. Statistical and Statistical Process Control (SPC) Software

Module 8. Six Sigma, Lean Six Sigma, Check Sheet and Food Processing

Module 9. Artificial Intelligence and Statistical Process Control

Module 10. Using Pareto Charts for Quality and Safety

Module 11. Histograms, Normal Distribution and other Charts

Module 12. Control Charts

Module 13. Scatter Plots and Correlation Coefficients

Module 14. Stratification Tools

Module 15. Ishikawa Diagram (Cause and Effect Diagram)

Module 16. The Failure Effects Mode Analysts ( FEMA)

Module 17. Hypothesis and Hypothesis Testing

Module 18. Process Mapping and Value Stream Mapping (VSM)

Module 19. Quality Control and Six Sigma

Module 20. Test Statistics

Module 21. Prerequisite Programs

Module 22. Preliminary Steps

Module 23. Food Safety Hazards

Module 24. Conduct Hazards Analysis

Module 25. Determine Critical Control Points

Module 26. Establish Critical Limits

Module 27. Establish Monitoring Procedures

Module 28. Establish Corrective Action procedures

Module 29. Establish Verification Procedures

Module 30. Establish Record-Keeping and Documentation Procedures

Module 31. Implement, maintain, and reassess HACCP plans and systems

The creation of a scientifically based Food Safety Management System called Hazard Analysis and Critical Control Points (HACCP) by The National Aeronautics and Space Administration (NASA) and others in 1960’s ushered a new era in food safety and quality. The Food Safety Modernization Act (FSMA) of 2011 expanded the concept to apply to other products. The HACCP system was designed for astronauts and now is globally recognized by governments, academia and industries. HACCP was created as a process centric system and from the beginning was a perfect system to apply statistical process control to eliminate, prevent or reduce deviation, faults, failure and variations. The National Advisory Committee on Microbiological Criteria for Foods (NACMCF), who wrote seven principles of HACCP, defines “Criterion as a requirement on which a judgement or decision can be based. Control is defined as (a) To manage the conditions of an operation to maintain compliance with established criteria. (b) The state where correct procedures are being followed and criteria are being met. Critical Control Point is a step at which control can be applied and is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level. Control Measure is any action or activity that can be used to prevent, eliminate or reduce a significant hazard. NACMCF also defines Critical Limit as a maximum and/or minimum value to which a biological, chemical or physical parameter must be controlled at a CCP to prevent, eliminate or reduce to an acceptable level the occurrence of a food safety hazard. Critical limits may be based upon factors such as temperature, time, physical dimensions, humidity, moisture level, water activity (aw), pH, titratable acidity, salt concentration, available chlorine, viscosity, preservatives, or sensory information such as aroma and visual appearance. Critical limits must be scientifically based. The critical limits and criteria for food safety may be derived from sources such as regulatory standards and guidelines, literature surveys, experimental results, and experts.” The integration of HACCP, FSMA, and Food Statistical Process Control (SPC) is a powerful tool to achieve established criteria to enhance food safety and quality, increase efficiency, reduce deviation, fault, failure and to make a lean system that is sustainable. This course is designed to achieve all the above.